Collision Reduction – Commercial, Utility and Work Vehicles – Using Reflective High Visibility Panels

Author – Steven Cole – (contact number and email – 850-934-3157 or steve@reflectivestore.com) (Our online store – www.chevronpanels.com)

Studies in the US and overseas show that by using high visibility reflective sheeting, accidents can be reduced by as much as 41% on the high side and 15% on the low side. The differences in effectiveness are going to be affected somewhat by the brightness, color,contrast, size, type and placement of the reflective treatment or panels. These numbers apply to both rear end and side collisions.

In previous articles we have discussed the science of visibility or conspicuity and how to use high visibility reflective tapes or panels to reduce rear end collisions. We also discussed the most visible colors to use. In this article I want to cover the type (design), size and placement of the reflective treatment so that the maximum benefit is achieved. In other words, what should your panels look like, how big should they be, and where should you place them?

Type of Reflective Panel to Use (Design)

There are several panel designs and color schemes that can be used to mark the rear, sides and fronts of vehicles to make them more visible. As we discussed in part 2 of this series, a fluorescent lime yellow and either red or orange is a good choice for color combinations in that they provide contrast and are bright colors by themselves. The picture below shows the different configurations that panels can be made in. There may be more but these are the main ones.

All three of the panels styles above will grab an observers attention. The one with the words has the advantage of conveying a message at the same time. The bottom two are basic alternating color panels. The middle is a non slanting design and the bottom is a slanting design also called a chevron pattern. People choose the different designs for different reasons. The chevron is chosen because it is unique and is often more conspicuous, however, since it is used on fire trucks it is often associated with that application. Therefore, many companies or organizations will opt for the middle pattern or the message panel to differentiate their vehicles from fire trucks.

Reflective Panel Size

The NFPA (National Fire Protection Association) recommends that 50% of the rear of a fire truck be covered with reflective material in the form of a chevron pattern. The minimum reflectivity would be a type 1 or engineer grade. Also, any yellow or red is acceptable.

By using a highly visible prismatic material and using a fluorescent color a panels visibility factor increases substantially. For example, a prismatic fluorescent lime yellow reflects at a rate of 420 candelas. A standard yellow engineer grade reflects at about 70 candelas. This makes the prismatic fluorescent 6 times more reflective at night. Other research shows that the fluorescent lime/yellow is at least twice as visible in the daytime. It is felt that smaller, bright prismatic panels can do the job of much larger less reflective panels. It is recommended that you use prismatic grade material especially if you want to cover only a small portion of a vehicle. For non regulated vehicles the general rule is that you want to cover enough of the sides or rear of the vehicle to make it conspicuous without going overboard and creating a distraction. The picture below shows the different sizes and configurations that reflective panels come in.

Reflective Panel Placement on the Vehicle

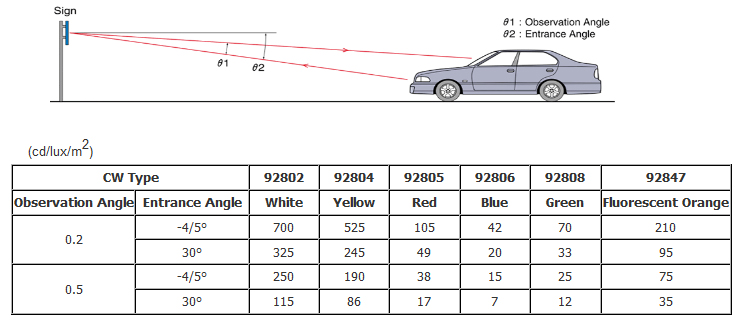

The last consideration is where to place the panels to gain maximum visibility and effectiveness. The rear of the vehicle would be the first area to consider followed by the sides. A stopped vehicle is most likely to get hit from the rear, however, side impacts for commercial vehicles are also common. Panels should be placed as low as possible or near the same level as the hood of a typical passenger car. Since panels are retro reflective and reflect light back to the light source, placing them too high can impede reflectivity. If you pull up behind a large truck at night you will notice that as you get closer, the lower reflective tapes still reflect and the higher ones begin to dull out. Just remember that light has to hit the tape from a cars head lights and then bounce back to the drivers eyes. If you have a panel on the upper portion of a van then the headlights will not even be close to hitting that panel as the vehicle gets close. From far out it will not matter as much but at closer distances it will. The picture in the chart below shows how this works.

- Part 1 – Introduction – Improving the Visibility of Vehicles

- Part 2 – Choosing Colors, Intensity, Contrast

- Part 3 – Selecting the Type, Size and Placement

Steven Cole (Economics, MBA – University of West Florida , Business & Innovation – Stanford University) 25 years of experience in the reflective safety business. Specializing in accident reduction for vehicles through increased visibility.